Moulding

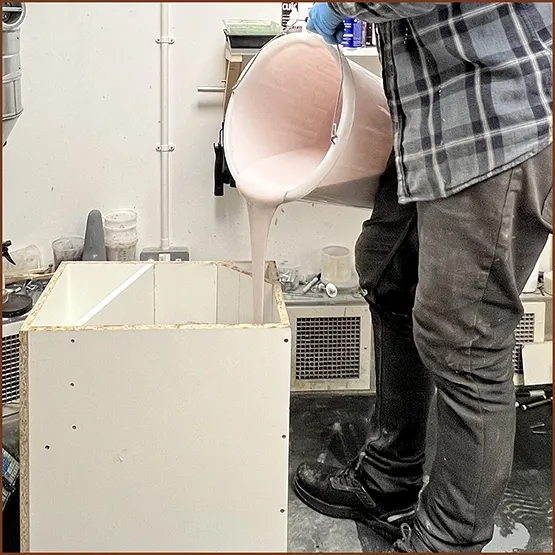

We pride ourselves in our ability to keep the integrity of the original clay sculpture alive so nothing is more important than the first silicone block mould. To harness the sheer weight of the material and avoid leakage we have to construct a very strong and perfectly sealed box to shroud the piece as closely as possible.

Cut-lines are predetermined and appropriate bleeds are added to allow any trapped air to escape and only then can we begin to pour in the pre-vacuumed liquid rubber. Once the rubber has hardened the mould is then skilfully cut allowing the removal of the now surplus clay sculpture.

From this point the process continues. Once a production prototype master has been cast from the initial block mould, and Matt has worked on it, it is then ready for claying up. This is where Nick, our Mould Maker, can determine both a satisfactory thickness for what will be a production mould using the clay to create

and engineer a desired outcome.